Earth Anchor Applications for Building and Landscape Design Tasks

High-Performance Anchor Equipments for Any Application

High-performance anchor systems are critical in guaranteeing safety and security and stability across a plethora of applications, from building and construction to aerospace. Comprehending the subtleties of different anchor kinds and their corresponding installation techniques is essential.

Types of Anchor Equipments

When thinking about the varied applications of support systems, what are the main types that professionals depend on for high-performance results? Support systems can be generally classified right into a number of kinds, each developed to meet certain demands based upon the nature of the load and ecological problems.

The initial group is mechanical anchors, that include development anchors, wedge supports, and screw anchors. These are generally employed in concrete and stonework applications, giving durable holding power through mechanical interlock or rubbing.

An additional considerable type is glue anchors, which utilize chemical bonding representatives to protect the anchor within the substrate. This kind is especially helpful in applications where high tensile strength and resistance to shear forces are needed.

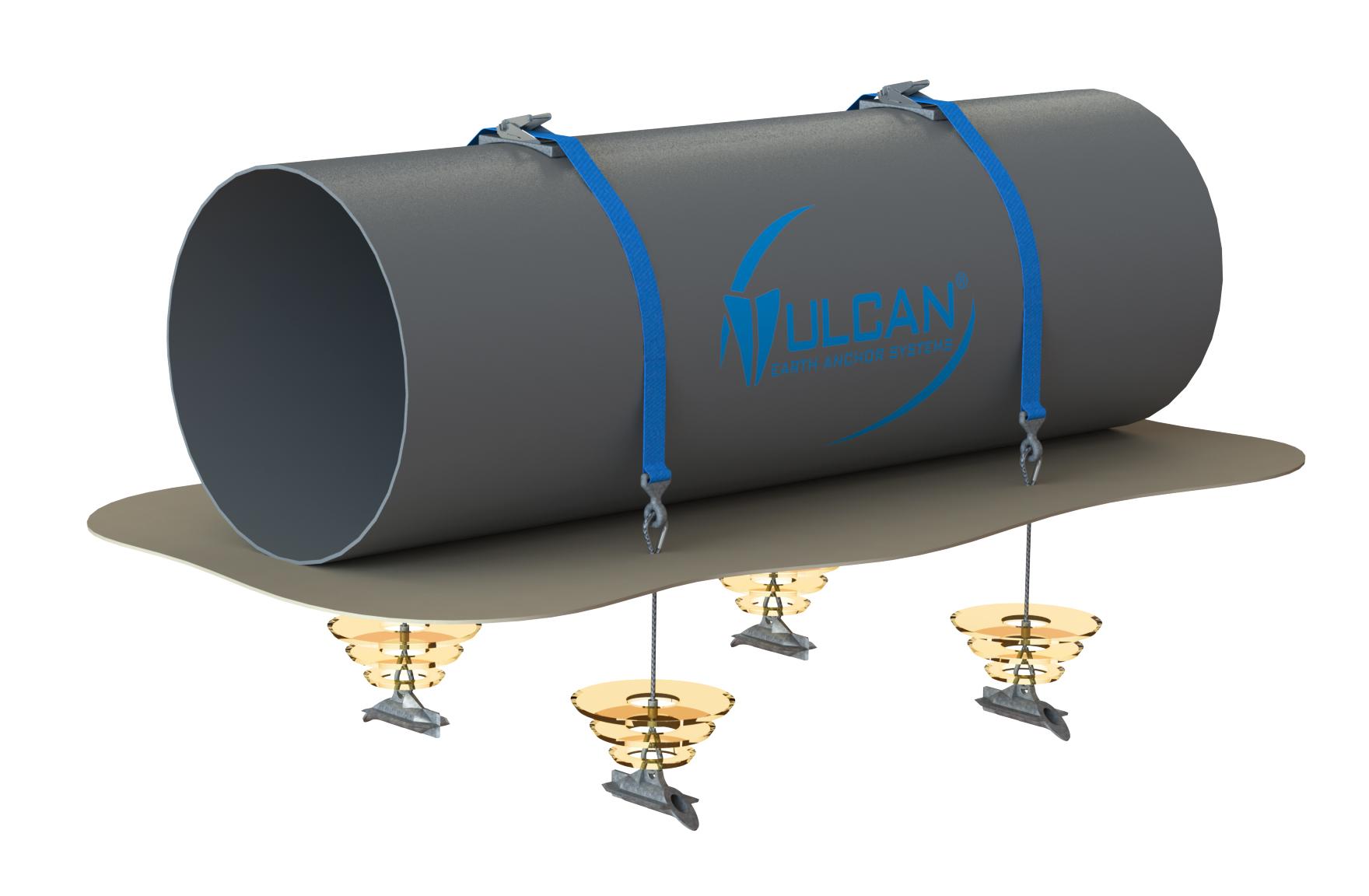

Furthermore, there are easy supports, such as deadman anchors, which count on the weight and resistance of bordering products to safeguard objects. They are usually utilized in exterior applications or where vibrant tons are existing.

Last but not least, there are specialized anchor systems like ground supports, which are made use of in civil engineering and building and construction projects for maintaining structures. Each sort of support system is designed with details performance metrics in mind, making sure optimum safety and security and effectiveness across numerous applications.

Key Features and Advantages

High-performance anchor systems provide a variety of key attributes and advantages that boost their performance in various applications. Among the key attributes is their superior tons ability, which guarantees stability and safety and security under significant anxiety conditions. This is accomplished via advanced materials and engineering designs, permitting trusted performance popular atmospheres.

Additionally, these systems often include innovative modern technology such as rust resistance and adaptability to different substratums. This not just prolongs their life expectancy yet likewise reduces upkeep prices, making them a cost-effective remedy over time. The convenience of high-performance anchor systems permits for seamless combination into various frameworks, enhancing their functionality throughout countless tasks.

Another remarkable advantage is convenience of installment. Lots of high-performance supports are created for straightforward and quick release, decreasing labor time and raising overall task performance. Their lightweight nature helps with transport and handling, contributing to structured operations.

Applications in Numerous Industries

In the transportation sector, high-performance supports are employed to secure road and rail facilities, contributing to the security of passengers and vehicles. Their integrity is paramount in stopping architectural failures that might lead to catastrophic mishaps. In addition, in the renewable energy sector, these anchors are crucial for protecting wind turbines and photovoltaic panel installations, ensuring they endure environmental tensions while making the most of effectiveness.

The aerospace sector additionally makes use of innovative anchoring remedies to safeguard parts throughout manufacturing and transport, where accuracy and dependability are important. In each of these applications, the next page selection of ideal support systems can considerably influence general project success, highlighting the versatility and requirement of high-performance supports across various industrial landscapes.

Setup Techniques and Tips

Proper installation of high-performance support systems is vital to their performance and longevity. To make sure ideal efficiency, it is vital to comply with well established installation methods tailored to the certain kind of support system and application.

Begin by completely analyzing the installment website, consisting of the substrate problems, lots requirements, and ecological factors. Exact measurements and positioning are important; use laser degrees or plumb lines to preserve accuracy. When boring, select the ideal little bit size and kind for the anchor system, making sure accurate and clean holes to avoid material damage.

Utilize the recommended torque setups throughout securing to avoid under-tightening or over-tightening, which can compromise the anchor's honesty. Additionally, follow the producer's standards pertaining to spacing and edge distances to maximize tons distribution and decrease prospective failure points.

Always utilize individual protective devices (PPE) during the installment process, and take into consideration making use of specialized devices developed for high-performance anchors to enhance efficiency and safety and security. Conduct an extensive assessment post-installation to validate that all elements are safely fastened and in placement, making sure the support system is prepared to perform under anticipated tons.

Maintenance and Security Considerations

To ensure the long life and dependability of support systems, regular maintenance and security factors to consider have to be focused on. Regular evaluations are necessary to recognize deterioration, deterioration, or any architectural shortages that might compromise the anchor's efficiency. An extensive maintenance timetable should include checking the integrity of support elements, such as screws, welds, and plates, and a knockout post making certain that all links are safe and secure.

Additionally, environmental aspects can considerably affect support systems. Exposure to severe weather condition problems or destructive substances can accelerate degeneration. Using protective finishings or using corrosion-resistant materials can enhance toughness and extend service life.

Security factors to consider are paramount; customers should stick to producer guidelines relating to lots limitations and functional procedures. Educating workers on appropriate use and potential hazards is crucial in protecting against crashes. Executing a safety monitoring system that includes normal drills and feedback systems can cultivate a culture of safety and security.

Final Thought

In verdict, high-performance anchor systems represent an important innovation throughout multiple markets, providing phenomenal lots capability, deterioration resistance, and versatility. Routine maintenance and complete assessments better improve their performance, establishing these support systems as important components in protecting frameworks and equipment.

High-performance anchor systems are critical in continue reading this ensuring security and stability across a wide variety of applications, from building to aerospace.High-performance support systems offer a range of vital functions and benefits that boost their performance in different applications. The convenience of high-performance anchor systems enables for seamless combination right into different structures, boosting their usability throughout various tasks.

In diverse markets, high-performance support systems play a crucial duty in ensuring architectural honesty and safety and security (Earth Anchor).In verdict, high-performance support systems stand for a critical technology throughout multiple sectors, providing phenomenal lots capacity, deterioration resistance, and adaptability